Layer:2L

Base Material:Alu

Board Thickness:0.2mm

Unit Size:155.02 x155.02 mm

Min hole size:0.2mm

Panel Size:155.02 x 155.02 mm

Total Holes:/

Copper OZ:2OZ

silkscreen:Black

Min Hole Copper Thickness:20um

Surface Finishing:ENIG Thickness

Solder Mask:White

|

|

|

|

Feature

1. Adopt surface mount technology (SMT);

2. Highly effective treatment of thermal diffusion in eucalyptus oil circuit design;

3. Reduce the operating temperature of the product, improve the power density and reliability of the product, and extend the service life of the product;

4. Reduce product volume and hardware and assembly costs;

5. Replace fragile ceramic substrate for better mechanical durability.

Aluminum Base Copper structure

PCB aluminum base copper clad plate is a kind of metal circuit board material, which consists of copper foil, thermal insulation layer and metal base plate. Its structure is divided into three layers:

Cireuitl.Layer line Layer: copper clad plate equivalent to ordinary PCB, line copper foil thickness loz to 10oz.

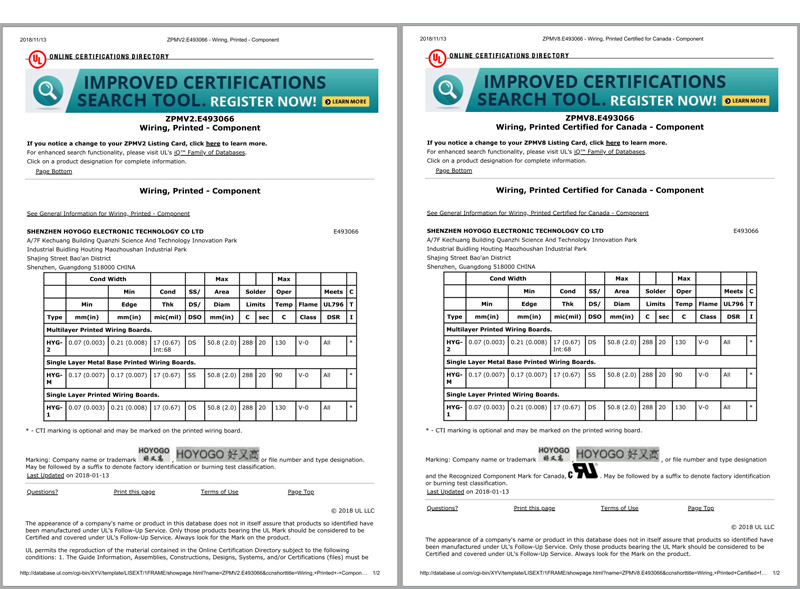

Dielcctric Layer insulation: the insulation Layer is a Layer of low thermal resistance thermal insulation material.Thickness: 0.003 "to 0.006" inches is the core technology of aluminum coated copper plate, which has been certified by UL.

Base Layer substrate: metal substrate, usually aluminum or optional copper.Aluminum base copper clad plate and traditional epoxy glass cloth laminate.

PCB aluminum substrate consists of circuit layer, thermal insulation layer and metal base.Circuit layer (that is, the copper foil) usually formed after etching printed circuit, make component parts are connected, under normal circumstances, the circuit layer with a lot of current-carrying capacity, thus should use thicker copper foil and the thickness of the general 35 microns to 280 microns;Thermal insulation layer is the core PCB aluminum plate technology, it is usually made up of special ceramics fill special polymers, the thermal resistance is small, viscoelastic can good, has the ability of thermal aging, able to withstand mechanical and thermal stress.

T - 101, T - 111, T - 112, T - 113, T - 114 and T - 200, T - 300, T - 400, T - 500, T - 600 and other high-performance PCB aluminum plate thermal insulation layer is using this technology, has the extremely good thermal conductivity and electrical insulation properties of high strength;Metal base is aluminum plate support components, requires high heat conductivity, generally is aluminum plate, also can use copper (copper plate can provide better thermal conductivity), suitable for drilling, punching and shearing and cutting and other conventional mechanical processing.Compared with other materials, PCB has incomparable advantages.Suitable for SMT mounting on power module surface.No radiator, greatly reduced volume, excellent heat dissipation effect, good insulation performance and mechanical performance.

Aluminium substrate use

1. Audio equipment: input, output amplifier, balance amplifier, audio amplifier, preamplifier, power amplifier, etc.

2. Power equipment: switching regulator ` DC/AC converter ` SW regulator, etc.

3. Communication electronic equipment: high frequency increase ` filtering electrical ` transmitting circuit.

4. Office automation equipment: motor drive, etc.

5. Car: electronic regulator ` igniter ` power controller, etc.

6. Computer: CPU board ` ` floppy drive power supply device, etc.

7. Power module: inverter ` solid relay ` rectifier bridge, etc.

8. Lamps and lanterns lighting decoration: with the promotion and promotion of energy-saving lamps, the aluminum substrate applied toLED lamps has also been widely used.

|

|

|

Welcome to the HOYOGO website!

HONGKONG HOYOGO TECHNOLOGY CO.,LTD

SHENZHEN HOYOGO ELECTRONIC TECHNOLOGY CO.,LTD

Tel : (+86)-755-2300 1582

Fax : (+86)-755-2720 6126

Email : sales@hygpcb.com

Add: 7A Quanzhi Science and Technology Innovation Park,Shajing Street, Bao'an District, Shenzhen. 518104/ P.R.C.