[Product detail]

|

|

|

|

| Layer: 4 | Base Material :FR4 TG145 CTI>175 |

| Board Thickness: 1.6mm | Unit Size(mm) : 53.88 x 154 |

| Min hole size: 0.33mm | Total hole: 464 |

| W/S(mil): 7.8/10 |

Surface Finishing :Immersion Tin |

| Solder Mask:Green matt | silkscreen: White |

| [Multilayer Construction] |

PCB -model: 39091/01/Print High/P11-TLE0001-1 V3.xx.01

| 1.Layer | Top Layer | Filename: Dachm-high.GTL |

| 2.Layer | Internal Layer1 | Filename: Dachm-high.G1 |

| 3.Layer | Internal Layer2 | Filename: Dachm-high.G2 |

| 4.Layer | Bottom Layer | Filename: Dachm-high.GBL |

_____________________________________________________________________________________________________________________

Total Multilayer thickness: 1.60+ -0.16 mm

1.60+ - 0.16 mm thickness including copper,chemical Sn, solder resist.

| [Drill Tool Table] |

| Tool | Final diameter | count | comment |

| T01 | 0.30mm-0/+0.15 mm | 6 | plated |

| T02 | 0.40mm-0/+0.15 mm | 424 | plated |

| T03 | 1.02mm-0/+0.15 mm | 12 | plated |

| T04 | 1.30mm-0/+0.15 mm | 12 | plated |

| T05 | 1.35mm-0/+0.15 mm | 4 | plated |

| T06 | 2.60mm-0/+0.10 mm | 4 | non plated |

| T07 | 4.00mm-0/+0.10 mm | 2 | non plated |

|

|

|

|

|

|

|

|

|

Total number of drills: |

464 |

|

|

|

|

Total number of tools: |

7 |

| [Feature] |

ⅰ. Good surface roughness

ⅱ. has excellent electrical conductivity and weldability, can be repeatedly welded

ⅲ. Shen-Xin Lead-free, no pollution to the environment

ⅳ. Long storage period (one year)

ⅴ. Simple process and good work environment

ⅵ. The hardness of antimony tin is small, easy to wipe flowers

ⅶ. High demand for incoming materials (semiconductor requirements before sinking tin are uniform, no oxidation, fingerprints, glue stains, etc.)

ⅷ. Repair difficulties

ⅸ. Storage and transportation requirements are high

|

|

|

| [Compared] |

|

|

ENIG |

Immersion Silver |

OSP |

HASL Lead |

Immersion Tin |

|

Advantage |

1. The sedimentary layer is smooth, with strong hardness, and the surface is not easy to scratch 2. Has good electrical conductivity and multiple welding performance 3 long storage period (more than 1 year) |

1. Deposit formation 2. Has good electrical conductivity and weldability 3. Simple process control 4. Easy to rework and repair |

1.Low production cost 2. Simple process control 3. Simple rework |

1.Low production cost 2. Has good electrical conductivity and weldability 3 can be repeated welding 4. Long storage period (more than 1 year) |

1. Simple process control

2. Deposit formation 3. Good electrical conductivity and weldability 4 can be repeated welding 5. The storage period is one year |

|

shortcoming |

1. High production cost 2. Process control is more difficult 3. There is a potential black mat defect 4. Difficulties in repairs and rework |

1. Short storage period (6~12 months) 2 can not be repeated welding 3. Yin Yin surface yellow 4. High requirements for storage environment and transportation |

1.Short duration 2 can not be repeated welding |

1. The spray surface has poor smoothness;

2 fine pitch processing difficulties 3 high temperature processing board easy to change 4. Lead, serious pollution of the environment |

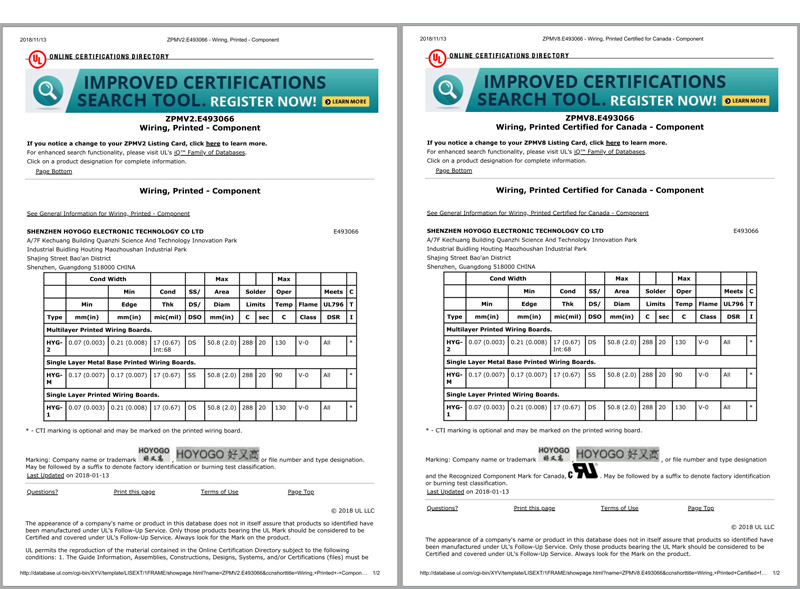

Welcome to the HOYOGO website!

HONGKONG HOYOGO TECHNOLOGY CO.,LTD

SHENZHEN HOYOGO ELECTRONIC TECHNOLOGY CO.,LTD

Tel : (+86)-755-2300 1582

Fax : (+86)-755-2720 6126

Email : sales@hygpcb.com

Add: 7A Quanzhi Science and Technology Innovation Park,Shajing Street, Bao'an District, Shenzhen. 518104/ P.R.C.