|

Layer:4 |

Base Material:FR4 TG135 |

|

Board Thickness:1mm |

Unit size:16.41x24.79mm |

|

W/S: 7.9/7 mil |

Surface Finishing:ENIG Thickness |

|

Solder Mask:Green |

Copper OZ:1OZ |

Multilayer Construction

PCB-model: E10-3102B / 310-802B

1.Layer Top Layer Filename: 310-802b.Top

2.Layer Internal Layer1 Filename: 310-802b.INTOP

3.Layer Internal Layer2 Filename: 310-802b.INBOT

4.Layer Bottom Layer Filename: 310-802b.Bot

Total multilayer thickness: 1,00+-1,10mm

1,00+-0,10mm thickness including copper,chemical Ni/Au,solder resist

|

|

|

|

Layer description

1.TOP layer: Designed as a top copper foil trace. If it is a single panel, there is no such layer.

2.BOMTTOM layer: Designed as a bottom copper foil trace.

3.TOP/BOTTOM SOLDER: The top layer/bottom layer is provided with solder-resisting green oil to prevent the copper foil from being covered with tin and remain insulated. Solder-resistant solder windows are opened at pads, vias, and non-electrical traces in this layer.

the pad in the design will open the window by default (OVERRIDE: 0.1016mm), that is, the pad exposed copper foil, external expansion 0.1016mm, will be tin on the wave soldering. It is recommended not to make design changes to ensure weldability;

the vias in the design will open the window by default (OVERRIDE: 0.1016mm), that is, through-hole copper foil, external expansion 0.1016mm, will be tin on the wave soldering. If it is designed to prevent tin on vias, do not expose copper. You must check the PENTING option in the additional properties of the vias, SOLDER MASK, and close the vias.

Third, in addition to this layer can also be a separate non-electrical wiring, the corresponding resistance welding green window. If it is on the copper foil trace, it is used to enhance the over-current capability of the trace, and it is treated with tin when soldering; if it is on the non-copper foil trace, it is generally designed for marking and special character silk screen printing. Character silk screen layer.

4.TOP/BOTTOM PASTE: This layer is generally used for solder paste on SMT components during reflow soldering process. It is not related to the printed board manufacturer's board. It can be deleted when exporting GERBER. The default can be kept during PCB design.

5.TOP/BOTTOM OVERLAY: Designed for a variety of silk screen logos, such as component number, characters, and trademarks.

6. MECHANICAL layerS (mechanical layer): Designed as a PCB mechanical shape, the default layer1 is the outline layer. Other layer2/3/4 can be used for mechanical dimensioning or special purpose. For example, layer2/3/4 can be used when some boards need to make conductive carbon oil, but the use of this layer must be clearly marked on the same layer.

7.KEEPOUT layer: Designed to inhibit the wiring layer, many designers also use the PCB mechanical shape. If there are KEEPOUT and MECHANICAL layer1 on the PCB, it mainly depends on the completeness of the two layers, generally MECHANICAL. Layer1 prevails. It is recommended to use MECHANICAL layer1 as the outline layer when designing. If using KEEPOUT layer as the outline, do not use MECHANICAL layer1 again to avoid confusion!

8. MIDlayerS (Intermediate Signal Layer): Mostly used for multilayer boards, our design is rarely used. It can also be used as a special purpose layer, but the use of this layer must be clearly identified on the same floor.

9.INTERNAL PLANES (Internal layer): Used for multilayer boards. Our design is not used.

10. MULTI layer: Via pad layer.

11.DRILL GUIDE (Drilling Positioning Layer): The centering coordinate layer of the drilling of the pad and via.

12. DRILL DRAWING: Describes the drill hole size of the pad and via.

PCB terminal requirements

A printed circuit board is a printed circuit board that is designed to form a point-to-point connection and a printed component on a general-purpose substrate. The main function of the printed circuit board is to enable various electronic components to form a predetermined circuit connection and perform relay transmission.

The manufacturing quality of PCB not only directly affects the reliability of electronic products, but also affects the integrity of the signal transmission between the chip and the chip. The level of industry development can reflect the development speed and technology level of a country or region's electronic information industry to some extent. .

The PCB's end demand can be divided into enterprise-level user demand and individual consumer demand. Among them, enterprise-level user needs are mainly concentrated in the fields of communication equipment, industrial control medical, and aerospace, etc. Related PCB products often have features such as high reliability, long service life, and strong traceability, and are more stringent for the certification of corresponding PCB companies. Longer certification cycle.

|

|

|

|

Personal consumer demand is mainly concentrated in the fields of computers, mobile terminals, and consumer electronics. The related PCB products are usually light, thin, and flexible. The terminal needs are relatively large, and the corresponding PCB companies are required to have large-volume supply capabilities.

PCB batch requirements are divided into small-batch boards (below 20m2), mid-batch boards (20m2-50m2), and large-batch boards (above 50m2)

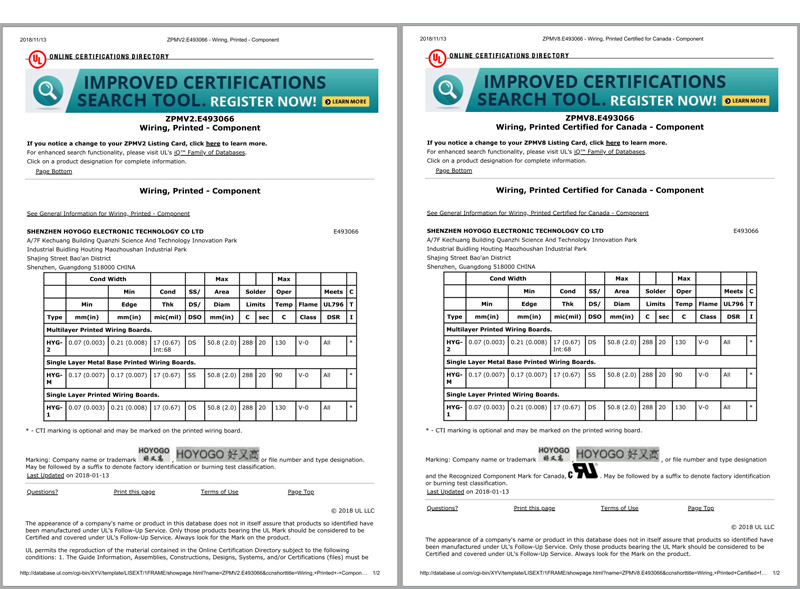

Welcome to the HOYOGO website!

HONGKONG HOYOGO TECHNOLOGY CO.,LTD

SHENZHEN HOYOGO ELECTRONIC TECHNOLOGY CO.,LTD

Tel : (+86)-755-2300 1582

Fax : (+86)-755-2720 6126

Email : sales@hygpcb.com

Add: 7A Quanzhi Science and Technology Innovation Park,Shajing Street, Bao'an District, Shenzhen. 518104/ P.R.C.