Product detail

| Layer: 6L | Base Material: FR4 TG170 |

| Board Thickness: 1.6mm | Unit Size: 46.5 x 52.7 |

| Min hole size: 0.25mm | Panel Size: 108.4 x 76 |

| Total Holes: 432/pcs |

Copper OZ:1OZ |

| W/S(mil):5/5.9 | Min Hole Copper Thickness:20um |

| Surface Finishing:ENIG Thickness & Gold finger & Impedance control | Solder Mask: Purple |

|

|

|

|

Feature

1. Prevent short circuit and other problems caused by soldering tin overflow.

2. During wave-peak welding, the welding resistance layer is particularly important, which can prevent non-welding points from being contaminated with soldering tin, etc.

3. Can effectively protect the circuit from moisture, etc.

4.It has superior conductivity, wear resistance, oxidation resistance and low contact resistance

Gold finger

gold-plated edge-conncetion --Gold finger at the Edge node of the circuit board

USES:Mainly used for compression contact with connection of the connector shrapnel and conductive interconnection, this is because the gold will never rust and electroplating processing has a very easy, appearance is good-looking, so almost all the contact surface of the electronic industry to choose gold PCB gold in gold finger board in more than 140 knoop hardness, with 30 u but in the loading on board (substrate),Is equipped with a number of gold bearing pad used for COBchip chip on Board with gold line between wire bond is a kind of hot pressing type welding way to interconnect the other factors should use soft layer of gold and gold thread fusion, usually under 100 knoop hardness of gold known as soft gold its hard gold is more strict quality requirements, in addition, the plating layer with solder and the thermal conductivity is also often used for solder joints and heat dissipation on the surface of the purposes

Quality detection

1. Defect of gold finger plating quality

A. throwing gold: the gold plating layer is not well adhered to the underlying metal;

B. Pinhole: tiny holes appeared on the gold surface, but the bottom metal did not penetrate and expose;

C. rough: not smooth, with concave and convex areas

D. Bad color, white or black on gold fingers

|

|

2. inspection methods:

A. Appearance inspection: put the plate under the light source and check whether there are defects such as needle holes, bad color, uneven electroplating and roughness

B. Peel strength: test the peel strength with 3M-600 adhesive paper. No gold or nickel shall be on the adhesive paper after the test

C. thickness of gold and nickel: put the gold finger plate under the testing machine and measure the thickness of gold and nickel with the X-ray test program

3. Gold finger plating quality requirements:

A. gold fingers have a uniform color and luster appearance;

B. tin is not allowed in the middle area of the gold finger

C. the maximum length of the gold finger on the green oil on the gold finger shall not exceed 1/6 of the length of the entire gold finger plate;

D. the appearance of gold fingers is smooth without roughness

E. the thickness of gold and nickel shall meet the customer's requirements

ENIG Thickness advantage

1. The thickness of gold is much thicker than that of gold plating, and the gold plating will be golden yellow.

2. Sinking gold is easier to weld than gold plating, which will not cause bad welding and cause customer complaints.The stress of sinker plate is more easy to control, and it is more beneficial to the processing of boding products.At the same time because sinking gold is softer than gold plating, so sinking gold plate does not wear gold fingers.

3. Only the welding plate has nickel gold on it, and the signal transmission in the skin effect will not affect the signal in the copper layer.

4. Compared with gold plating, the crystal structure is denser and less prone to oxidation.

5. As the wiring becomes more and more dense, the line width and spacing have reached 3-4mil.Gilding is easy to produce short wire.The gold plate only has nickel gold on the welding plate, so it will not produce short circuit wire.

6. Only the welding plate has nickel gold on it, so the resistance welding on the line is more firmly combined with the copper layer.The engineering will not affect the spacing when making compensation.

7. Generally, it is used for relatively high demand boards with good flatness. Generally, sinking gold is used.The leveling property of gold plate is as good as that of gold plate.

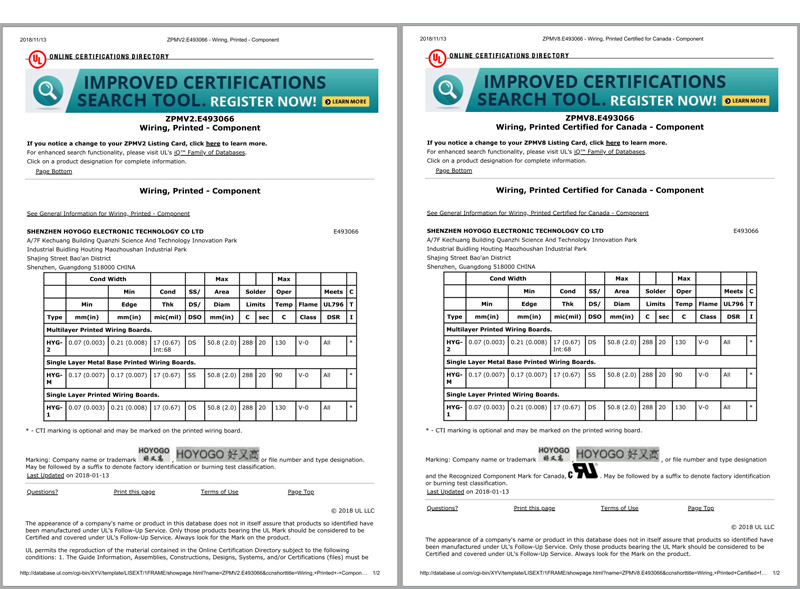

Welcome to the HOYOGO website!

HONGKONG HOYOGO TECHNOLOGY CO.,LTD

SHENZHEN HOYOGO ELECTRONIC TECHNOLOGY CO.,LTD

Tel : (+86)-755-2300 1582

Fax : (+86)-755-2720 6126

Email : sales@hygpcb.com

Add: 7A Quanzhi Science and Technology Innovation Park,Shajing Street, Bao'an District, Shenzhen. 518104/ P.R.C.