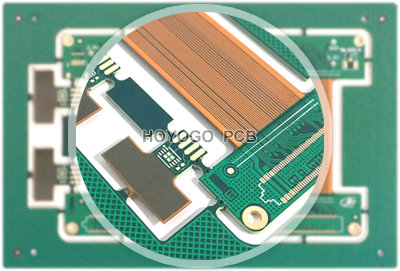

The rigid-flex board is a combination of flexible board and rigid board. It is a cleverly designed connection between a thin layered flexible PCB and a rigid PCB. In terms of materials, the material of PCB is FR4 and the material of FPC is PI or PET. There are problems such as bonding between the two materials and different shrinkage rates of heat and pressure. The rigid-flex board brings great convenience to the design of electronic products. So what are its specific advantages?

1. The rigid-flex board has a short transmission path and a small conduction aperture. But it can be folded in half, bent, and wired in three dimensions. It can also change the shape according to the space limitation, reduce the volume of the application product to reduce the volume of the application product, greatly reduce the weight, increase the function and reduce the cost.

2. When the FPC is connected through the connector, there will be problems of inconvenience and reliability of installation, and problems such as short-circuiting and falling off. The rigid-flex board can not only solve the problem of FPC installation reliability, but also prevent electrostatic interference and high and low temperature resistance.

3. Although the price of the rigid-flex board has increased, it saves the cost of the connector, reduces the installation time and repair rate, and improves the productivity and reliability.

4. The folding of the rigid-flex board does not affect the signal transmission function. Since the rigid-flex board is not connected through a connector, the wiring continuity is better and the signal integrity is better. The main control board and the sensor board can be integrated by using the rigid-flex board, which solves many problems and also meets the structural design requirements.

5. It can not only be folded in half, bend, reduce space, but also can weld complex components. At the same time, it has a longer lifespan than a flat cable, more reliable stability, and is not easy to break, oxidize and fall off. It is very helpful to improve product performance.

6. The design of the rigid-flex board can use a single component to replace the composite printed circuit board connected by multiple connectors, multiple cables and ribbon cables, with stronger performance and higher stability. The design of related products can reduce assembly man-hours and errors, and increase the service life of the product.

HOYOGO is an international, professional, reliable rigid-flex PCB manufacturer. We have 2 factories production bases. Our production is strictly following high quality system of automotive products, we certified with ISO9001, ISO14001,ISO13485 and TS16949 and C-UL-S. All products strictly follow acceptance standard IPC-A-600-H and IPC-6012.