As the demand for automotive electronic equipment continues to grow, how to improve the reliability and performance of electronic components has become a critical problem. In this regard, ceramic PCBs have gradually become an ideal solution due to their excellent electrical insulation and thermal conductivity, especially their stable performance in high-temperature environments.

Superior Performance of Ceramic Substrates

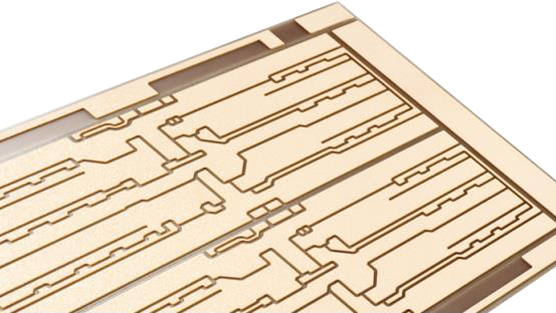

Ceramic PCBs usually use ceramic substrate materials such as alumina (Al₂O₃) or aluminum nitride (AlN). Among them, alumina is a common ceramic material with moderate cost, excellent mechanical strength, and outstanding electrical insulation performance. Therefore, it is widely used in various fields including electronic equipment. Aluminum nitride is highly regarded for its excellent thermal conductivity and relatively low thermal expansion coefficient, which is particularly suitable for high-power system applications that have a high tolerance to strong thermal environments.

1. Electrical Insulation

Due to its own high resistivity, ceramic material can effectively prevent current leakage in high voltage environments, thereby providing extremely high electrical insulation performance. This is especially important for components in automotive electronic equipment that require high voltage operation, as it can effectively prevent faults such as short circuits or electric shocks.

2. Thermal Conductivity

Compared with traditional glass fiber or plastic substrates, the thermal conductivity of ceramic substrate is significantly improved. For example, the thermal conductivity of aluminum nitride ceramic material can reach 170-220 W/m·K, which is dozens of times that of traditional FR4 materials. Its efficient thermal conductivity enable the ceramic substrate to quickly conduct away the heat generated during operation, preventing components from being damaged due to overheating, thereby improving the reliability and service life of the entire system.

Applications in High Power Automotive Electronics

The high power demands of automotive electronics make heat dissipation a key challenge in the design process. Especially in the application of electric vehicles and hybrid electric vehicles, Battery Management Systems (BMS), Electric Drive Systems, etc. need to handle a large amount of power conversion and transmission, which requires the circuit board to be able to withstand higher operating temperatures and achieve effective heat dissipation.

1. Battery Management System

The Battery Management System (BMS) is a core component of electric vehicles. Its main task is to comprehensively monitor and manage the operating status of the battery pack. BMS is responsible for processing various complex current and voltage signals, which places extremely high demands on the electrical insulation and thermal conductivity of the circuit board to ensure the safe and stable operation of the system. In this regard, ceramic PCBs perform well, and their high electrical insulation and high thermal conductivity can meet the strict requirements of BMS for circuit boards.

2. Electric Drive System

The electric drive system mainly includes key components such as motor controller and inverter, which will generate a lot of heat during operation. If the heat cannot be dissipated effectively, system performance may be degraded or even fail. The use of ceramic PCBs can greatly improve the heat dissipation performance of the system, ensuring that the electric drive system remains stable and efficient under high-power operating conditions.

Ceramic PCBs have become the first choice for high-power automotive electronic devices due to their excellent electrical insulation and thermal conductivity, especially their stability in high-temperature environments. The use of ceramic substrate materials such as alumina and aluminum nitride can improve the reliability and service life of electronic components and effectively solve the heat dissipation problem in high-power applications. With the continuous advancement of automotive electronic technology, the application prospects of ceramic PCBs will become broader.

HoYoGo is an international, professional and reliable ceramic PCB manufacturer. We have obtained ISO13485 certification. At the same time, we consistently adhere to the highest industry standards for certification requirements for our production teams, engineering teams, and procurement teams. In addition to producing ceramic PCBs and various other PCBs, we can also provide you with preferential prices for ceramic materials. If you have related needs, you are welcome to send us your inquiries!