Ceramic PCB plays a vital role in the new energy industry, and is particularly widely used in high-power and high-temperature environments. The main materials of ceramic PCB include alumina(Al2O3) and aluminum nitride (AlN), etc. These materials have excellent thermal conductivity and electrical insulation, making them an ideal choice in the the new energy field. The following are the main applications of ceramic PCB in the new energy industry:

1. Solar Photovoltaic

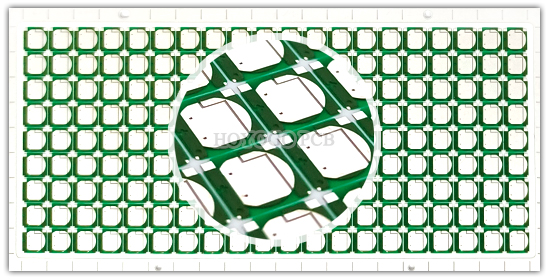

1) Photovoltaic Module Packaging

Ceramic PCBs are widely used in the packaging of photovoltaic modules in the field of solar photovoltaics because they can effectively conduct the heat energy generated by the modules, thereby improving the efficiency and stability of the modules. In addition, ceramic PCBs have excellent mechanical strength and can withstand large mechanical stress, further improving the durability and reliability of modules. Therefore, ceramic PCBs are very suitable for applications with high power density and requiring long-term stable operation.

2) Inverter

Solar inverters convert the direct current generated by photovoltaic cells into alternating current. During this process, the inverter generates a lot of heat due to the increase in conversion efficiency. The high thermal conductivity of ceramic PCB can effectively dissipate heat, avoid damage to the inverter in high temperature environment, and improve system stability. In particular, alumina ceramic PCBs have the advantage of relatively low cost and are widely used in inverters.

2. Wind Power Generation

The power modules in wind power generation systems also require PCBs that are resistant to high temperatures and voltages. Ceramic PCBs, with their excellent thermal management and mechanical stress properties, can be used in control modules of wind power generation systems to help manage complex power conversion and transmission. The high reliability of ceramic PCB enables it to work in harsh outdoor environments and extend the service life of the equipment.

3. Energy Storage Systems

Lithium-ion battery components in energy storage systems have strict requirements on heat dissipation and conductivity. With its excellent thermal and electrical conductivity, ceramic PCB can effectively improve the heat dissipation efficiency of battery components, maintain temperature stability, and improve charging and discharging performance. This makes it have wide application potential in battery management systems (BMS) and power modules with high power density and high heat dissipation requirements.

HoYoGo is an international, professional and reliable ceramic PCB manufacturer, with many years of experience in ceramic PCB production. We can realize the production of high-tech, high-quality, high-difficulty and high-performance boards, and can guarantee the quality and reliability of each product delivered to customers. If you have ceramic PCB needs, welcome to contact us!