Flexible PCBs are widely used in automotive electronics due to their bendable, foldable and lightweight properties, especially in complex environments such as confined spaces and dynamic conditions. The following are the applications of flexible PCB in the automotive field:

1. Instrument Panels and Display Connections

Flexible PCB can not only transmit real-time data of multiple complex sensors in the dashboard, but also provide stable signal and power support for the display screen. It is particularly worth mentioning that in the application of large-size or special-shaped displays, flexible PCBs can easily adapt to the special shapes of these displays, thereby optimizing the interior space layout.

2. Internal Circuit of Car Doors

In order to accommodate the numerous electronic devices inside the door, wiring for systems such as electric windows, audio, and lighting needs to be performed within a limited space. These devices are usually in a dynamic working environment, and the bending performance of the flexible PCB can effectively withstand the opening and closing actions of the car doors, thereby ensuring the long-term stable operation of the system.

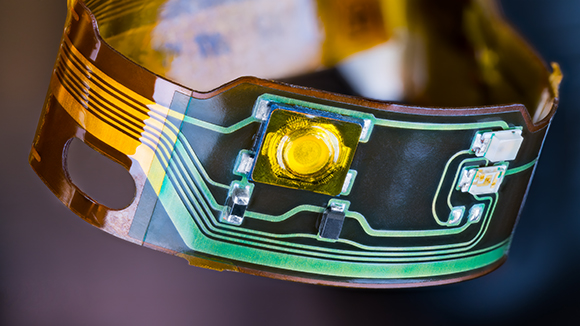

3. Camera Systems

In the automotive field, flexible PCBs address the challenges of complex wiring configurations required for high-demand systems such as reversing cameras and panoramic view systems. Their characteristics enable flexible wiring arrangements within the vehicle body. Flexible PCBs are designed to ensure stable transmission of high-definition camera signals, reducing wiring complexity and the dependency on traditional cables.

4. Engine and Transmission System Control

Flexible PCBs are widely used in engine management systems and transmission system control modules to meet the demands of high temperature and extreme environments. Their excellent heat resistance and vibration resistance ensures that system maintains normal operation under harsh conditions, while improving control accuracy and response speed.

5. Seat Control Systems

The seat adjustment systems in vehicles, including functions like electric adjustment, heating and massage functions, require complex wiring within tight spaces. Flexible PCB can be arranged within the seats to simplify the connection structure while ensuring the reliable electrical performance.

6. Interior Lighting Control Systems

In-car lighting systems, including ambient lights and reading lights, also often use flexible PCBs. Their ability to adapt to the curved surfaces of the vehicle provides an efficient, space-saving wiring solution, meeting both aesthetic and functional lighting requirements in vehicles.

Through these applications, flexible PCBs not only improve the performance of automotive electronic systems, but also help optimize the utilization of interior space and improve vehicle reliability and safety.

HoYoGo is an international, professional and reliable flexible PCB manufacturer. Our production strictly adhere to the high quality system and has passed ISO9001, ISO14001, ISO13485, TS16949 and C-UL-S certifications. All products comply with the acceptance standards of IPC-A-600-H and IPC-6012. Our product quality is widely recognized by customers in Europe and America. If you have any related needs, you are welcome to send us an inquiry.