In daily life, it is increasingly evident that medical electronic devices are trending toward greater intelligence and portability. Against this backdrop, multilayer flexible PCB, with their unique characteristics, have become indispensable components in medical electronic devices.

1. Characteristics of multilayer flexible PCB

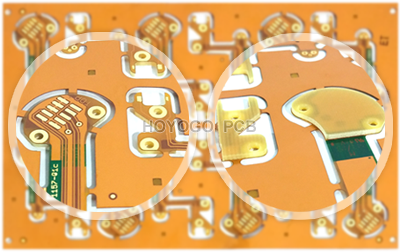

Multilayer flexible PCB is composed of multiple conductive and insulating layers, offering notable advantages such as high flexibility, lightweight design, and space-saving properties. Compared with traditional rigid PCB, FPCs are better suited to meet complex spatial requirements. At the same time, circuit boards made from flexible materials can reduce the overall weight of devices, enhancing their portability. Moreover, their performance of multilayer flexible PCB in terms of shock and pressure resistance ensures higher reliability in medical environments.

2. Application Examples in Medical Electronic Devices

1) Medical Imaging Equipment

In the field of medical imaging equipment, such as ultrasound, CT and MRI equipment, multi-layer flexible PCBs are widely used in signal transmission and data processing modules. Given that these devices need to process data efficiently in compact spaces, the high-density integration characteristics of multilayer flexible PCBs make them an ideal choice. In addition, multi-layer flexible PCBs can also provide more excellent electrical performance, ensuring the reliability and accuracy of signal transmission. Furthermore, multi-layer flexible PCBs offer superior electrical performance, ensuring reliable and accurate signal transmission.

2) Portable Monitoring Equipment

In recent years, portable monitoring devices, such as heart rate monitors and smart watches have become increasingly popular. The lightweight and flexible nature of multilayer flexible PCBs makes them ideal for these applications. Their ability to conform to various shapes and curves not only reduces device size but also enhances user comfort. The multilayer design of the device ensures a well-organized internal circuit layout, minimizing interference and signal loss.

3) Endoscope System

In endoscopy systems, multilayer flexible PCBs are used to connect cameras, light sources, and processors. Their flexibility allows endoscopes to navigate easily and adapt to complex physiological structures. The multilayer design not only ensures stable signal transmission and facilitates the rapid processing of complex signals, providing doctors with clear real-time images and improving diagnostic accuracy.

The applications of multilayer flexible PCBs in medical electronic devices extend far beyond these examples. Their widespread use has undoubtedly propelled the advancement of medical technology. The superior characteristics of multilayer flexible PCBs enable medical devices to become more compact, intelligent, and efficient, while simultaneously improving the quality and efficiency of medical services.

HoYoGo is an international, professional and reliable multilayer flexible PCB manufacturer. We have obtained ISO13485, we have consistently held our production, engineering, and procurement teams to the highest industry certification standards. When there is a conflict between Efficiency and PCB's Quality, our priority is always to maintain PCB's Quality. If there is a conflict between Growth Rate and PCB's Quality, we prioritize PCB's Quality over speed.