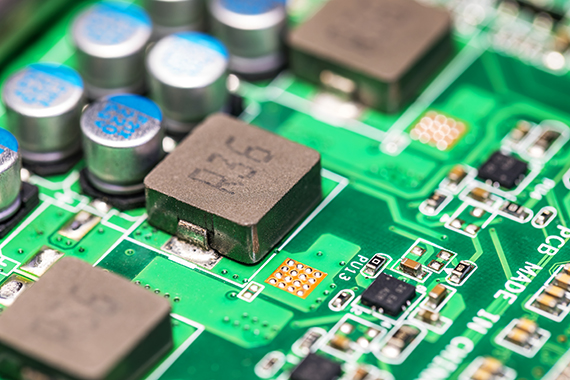

In industrial automation, PCBs play a vital role, they are the core components of automation equipment and systems. Here are some key applications of PCBs in industrial automation:

1. Programmable Logic Controllers (PLC)

Programmable logic controllers (PLC) are one of the most common control systems in the field of industrial automation. Its main function is to monitor and precisely control machinery and process in real time. In the PLC system, industrial automation PCB plays an indispensable and important role, mainly responsible for connecting and supporting various electronic components such as processors, memory, input/output interfaces, etc.

2. Human-machine Interface (HMI)

HMI devices provide the interactive interface between operators and industrial automation systems. Among these devices, industrial automation PCBs assume key functions such as driving displays, touch screens, power management, and communication modules.

3. Sensor and Actuator Interfaces

In the field of industrial automation, devices such as sensors and actuators are widely used. These devices are connected to the control system through PCB. In this application, industrial automation PCB plays a vital role, taking on tasks such as signal processing, data transmission, and power supply.

4. Industrial Robots

Industrial robots rely on complex control circuits and power systems, and industrial automation PCBs undertake most of the circuit integration work in this process. They are mainly used to support motion control, power transmission and communication functions.

5. Driver and Power Modules

Industrial automation equipment requires precise motor control and stable power supply. Industrial automation PCBs provide the necessary electrical connections and heat dissipation in drive and power modules.

6. Industrial Communication Networks

Industrial automation systems usually require real-time data exchange, and industrial automation PCBs play a key role in building and maintaining industrial communication networks, such as Ethernet/IP, CAN bus, Modbus, etc.

Furthermore, in industrial automation, PCBs not only need to have high reliability and durability, but must also be able to withstand harsh industrial environments such as high temperature, high humidity, and electromagnetic interference. Therefore, when designing and manufacturing PCBs for industrial automation, special consideration needs to be given to factors such as material selection, layer design, thermal management, and electromagnetic compatibility (EMC).

HoYoGo is an international, professional and reliable PCB manufacturer. We have obtained ISO13485 certification and have consistently adhere to the highest industry standards for our production, engineering and procurement teams. When there is a conflict between Efficiency and PCB's Quality, our priority is always to maintain PCB's Quality. If there is a conflict between Growth Rate and PCB's Quality, we prioritize PCB's Quality over speed.