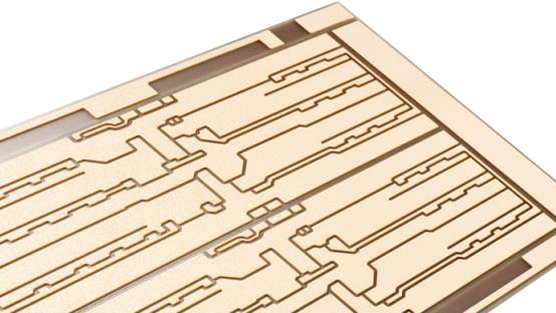

Ceramic PCBs play a crucial role in medical electronic devices due to their exceptional thermal conductivity, high insulation, high-temperature resistance, and biocompatibility. As medical technology continues to advance, the demand for enhanced stability and reliability in electronic devices increases, making ceramic PCBs an ideal solution.

1. High-power Medical Equipment

Medical equipment such as X-ray machines, CT scanners, and laser therapy devices typically require high-power electronic components that generate substantial heat during operation. Ceramic PCBs, such as those made from alumina and aluminum nitride, exhibit excellent thermal conductivity. They can quickly dissipate heat, preventing device overheating and enhancing the lifespan and reliability of the equipment.

2. Implantable Medical Devices

Implantable medical devices, including pacemakers, neurostimulators, and cochlear implants, demand circuit boards with stringent requirements for size, stability, and biocompatibility. Ceramic PCBs are not only compact and lightweight but resistant to corrosion in the body’s environment. They offer superior electrical performance, ensuring long-term stable operation of the devices. For example, aluminum nitride ceramic PCBs are widely used in high-precision implantable medical devices due to their high thermal conductivity and insulation properties.

3. Medical Sensors

Medical sensors such as glucose monitors, bioelectric sensors, and pulse oximeters require high precision, sensitivity, and longevity. Ceramic PCBs, with their low dielectric loss and high durability, are ideal substrate materials. For example, in in-vitro diagnostic (IVD) devices, ceramic PCBs can withstand high-temperature and high-humidity sterilization environments while maintaining measurement accuracy.

4. High-Frequency Medical Equipment

In high-frequency applications such as ultrasound diagnostic equipment, wireless medical communication devices, and millimeter-wave therapy equipment, ceramic PCBs offer advantages like low dielectric constant (Dk) and low dielectric loss (Df). These properties help reduce signal transmission losses and ensure the stability of high-frequency signals, thereby improving the diagnostic accuracy of medical equipment.

5. Laboratory Analysis Instruments

In precision laboratory equipment such as DNA sequencers and PCR (polymerase chain reaction) devices, ceramic PCBs provide high stability and strong chemical corrosion resistance, ensuring stable operation in extreme environments. For example, in the heating modules of PCR devices, ceramic PCBs can deliver uniform temperature distribution, enhancing the precision and efficiency of DNA amplification.

Ceramic PCBs, with their excellent heat resistance, thermal conductivity, electrical properties, and chemical stability, play a vital role in the field of medical electronics. As medical devices continue to evolve towards miniaturization, high precision, and enhanced reliability, the applications of ceramic PCBs will become even more widespread, providing a solid foundation for advancements in medical technology.

HoYoGo is an international, professional and reliable medical PCB manufacturer, and has obtained ISO13485 certification. We use advanced ceramic substrates such as alumina and aluminum nitride, combined with sophisticated manufacturing processes, to produce PCBs with high thermal conductivity, heat resistance, and excellent insulation. Strictly adhering to medical industry standards, we ensure every PCB we deliver is precise and reliable.