HDI blind and buried via PCB is a multi-layer circuit board that uses blind and buried via technologies to densely integrate circuits and signal lines. This design effectively reduces the circuit board area while improving signal transmission efficiency and achieving higher component integration. Compared to traditional circuit boards, HDI blind and buried via PCBs offer significant advantages in design flexibility, manufacturing precision, and electrical performance. Below are the main applications of HDI blind and buried via PCBs in autonomous vehicles:

1. Sensor Integration

Autonomous vehicles rely on various sensors to gather information about the surrounding environment, such as LiDAR, cameras, and ultrasonic sensors. HDI blind and buried via PCBs can perfectly integrate complex sensor circuits and provide efficient signal transmission, thus achieving high-precision, low-latency data acquisition. By reducing the space occupied by circuits, HDI blind and buried via PCBs enhance the flexibility of sensor designs.

2. Electronic Control Units (ECUs)

The electronic control units (ECUs) in autonomous vehicles are responsible for processing large amounts of real-time data. The high signal density and high-frequency transmission capabilities of HDI blind and buried via PCBs enable more efficient circuit layouts within ECUs, improving processing speed and accuracy to support the complex computations required by autonomous driving technology.

3. Communication Systems

Effective communication between vehicles (V2V) and between vehicles and infrastructure (V2X) is a crucial foundation for autonomous driving safety. HDI blind and buried via PCBs are widely used in wireless communication modules, where their high-speed and low-latency features ensure reliable data transmission. This enables the vehicle to respond quickly to changes in the surrounding environment, improving driving safety.

4. Power Management Systems

Autonomous vehicles require efficient power management to support various electronic devices. HDI blind and buried via PCBs are applied in power management circuits, where their excellent conductivity and heat dissipation performance help optimize power configuration and energy distribution, ensuring the stable operation of electronic devices.

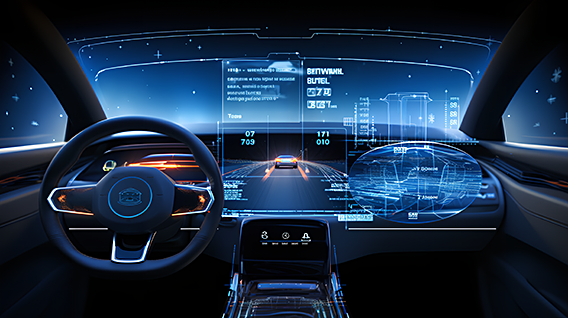

5. Infotainment Systems

Autonomous vehicles often feature advanced infotainment systems that provide navigation, communication, and entertainment functions. HDI blind and buried via PCBs offer compact designs and efficient signal transmission, ensuring fast response times and a smooth user experience for infotainment systems.

6. Trunk and Electric Door Control Modules

In the trunk and electric door control modules, HDI blind and buried via PCBs help reduce the number of wiring connections, simplify circuit design, and improve the reliability of control signal transmission. This is especially important for the automatic door-opening systems in autonomous vehicles.

Moreover, the long-term durability and safety of components in autonomous vehicles are critical. The high-quality materials and advanced manufacturing processes used in HDI blind and buried via PCBs ensure their reliability in various extreme environments. Whether subjected to high temperatures, humidity, or vibration, HDI blind and buried via PCBs can maintain excellent performance, reducing failure rates and providing a solid foundation for the reliable operation of autonomous driving technology.

HoYoGo is an international, professional and reliable automotive PCB manufacturer with a high level of automation and dedicated automotive production lines, with automotive boards accounting for 49% of our total. Our production strictly adheres to the high quality management system and has passed ISO9001, ISO14001, ISO13485 and TS16949 certifications. All products strictly follow the acceptance standards of IPC-A-600-H and IPC-6012. If you have related PCB needs, welcome to send us an inquiry.