In industrial production processes, humidity monitoring plays a vital role, directly impacting product quality and production efficiency in industries such as pharmaceutical, chemical and food processing. To meet the stringent requirements for humidity monitoring in industrial environments, ceramic substrate sensors are an ideal choice due to their stability and accuracy.

The Importance of Industrial Humidity Monitoring

In industries such as pharmaceuticals, chemicals and food processing, a moderate humidity environment is critical to product quality. Medicines may become ineffective in humid environments; Humidity fluctuations in chemical processes can adversely affect reaction efficiency and product quality. Improper humidity control during food processing can also cause product spoilage. Therefore, industrial-grade humidity monitoring needs to have accurate, fast and stable monitoring capabilities.

Advantages of Ceramic Substrate Sensors in Humidity Monitoring

1. High-Temperature Resistance

The ceramic substrate can maintain sensing accuracy in high temperature environments due to its excellent high temperature resistance. Therefore, it can achieve long-term stable operation in high-temperature environments such as metallurgy and chemical industry, ensuring the continuity of humidity monitoring.

2. High Reliability and Corrosion Resistance

Ceramic substrates have excellent corrosion resistance in humidity, acid and alkali environments, and can effectively avoid being affected by harsh environments. This product is suitable for harsh working environments such as high humidity and corrosive gases. It can significantly extend the service life of the sensor while also helping to reduce maintenance and replacement costs.

3. Low Power Consumption and Miniaturization

The unique low-energy design of the ceramic substrate is particularly suitable for long-term operation and also supports miniaturized design, making it easy to install in various industrial equipment, thereby saving both energy and space.

Application Cases

1. Pharmaceutical Industry: Ceramic substrate sensors provide highly accurate humidity monitoring during pharmaceutical production and storage, ensuring that products meet industry standards.

2. Chemical Industry: In environments with corrosive gases and high temperatures, ceramic sensors enhance equipment lifespan through their corrosion and heat resistance, reducing operational costs.

3. Food Processing Industry: Humidity control has a significant impact on the texture, taste and shelf life of food. Effective humidity control can stabilize the quality of food, and ceramic substrate sensors can achieve precise control of humidity, thereby ensuring the quality of food.

Future Development

In future development, ceramic substrate sensors will make continuous progress in intelligence, low power consumption and material optimization. Among them, intelligent sensors will be deeply integrated with Internet of Things technology to achieve real-time data transmission to the cloud, supporting more accurate data analysis and remote monitoring.

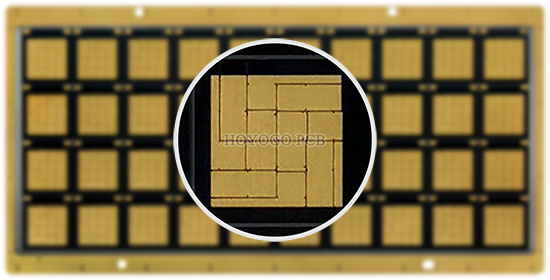

HoYoGo is an international, professional and reliable ceramic PCB manufacturer. Our production strictly follows the high quality system, and all products strictly follow the acceptance standards IPC-A-600-H and IPC-6012. And we can guarantee the quality and reliability of each product delivered to customers, we can also provide you with preferential prices for ceramic materials.