In an era where Internet of Things (IoT) technology is changing with each passing day, the importance of smart gateways as a bridge connecting the physical world and the digital world is self-evident. It is not only responsible for data collection, processing and transmission, but also undertakes the key task of converting communication protocols between devices. For companies that want to build efficient and stable IoT solutions, choosing the right PCBA manufacturing solution for smart gateway is crucial.

Overview of Smart Gateways

A smart gateway is a device that can intelligently manage, control and optimize data transmission between different devices or networks. It integrates multiple hardware components, such as processors, memory, network interfaces, etc., and implements complex communication protocol conversion, data processing, security control and other functions through embedded software. Smart gateways are widely used in smart homes, smart cities, industrial automation and other fields, and are the core components for realizing the intelligence and automation of the Internet of Things.

PCBA Manufacturing in Smart Gateways Mainly Involves the Following Key Links:

1. Design and Prototype Development

The PCB design of the smart gateway needs to cover many factors such as signal integrity, electromagnetic compatibility, and power consumption management. In addition, during the design process, its compatibility with multiple communication protocols must be ensured.

2. Components Selection and Welding

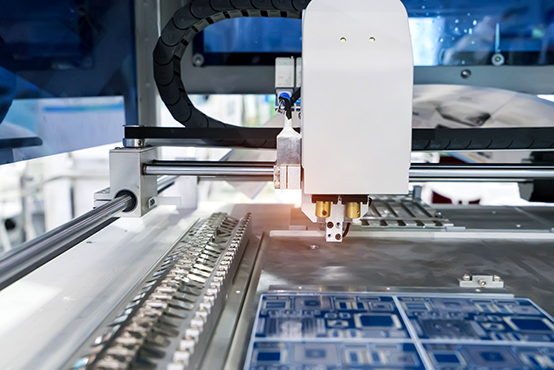

Due to the complexity and high requirements of the smart gateway functions, the selection of its components must be cautious. The selection of high-performance components such as microprocessors, wireless communication modules, memory and sensors will directly affect the functionality, power consumption and cost of the smart gateway. In the PCBA manufacturing process, surface mount technology (SMT) is a key process, which uses automated equipment to accurately place components on the PCB surface and uses a reflow soldering process to connect them, ensuring the firmness of each component and good electrical performance.

3. Testing and Verification

After the PCBA manufacturing of the smart gateway is completed, its various components and functional modules must undergo rigorous testing and verification to ensure the stability of its operation. Specifically, it includes circuit integrity test, signal transmission test, wireless communication performance test and thermal management test. These tests are designed to ensure that the smart gateway can operate stably in various operating environments and guarantee the reliability of its data processing, communication and control functions. In addition, functional testing also includes firmware loading and verification to ensure that the smart gateway can successfully connect and interact with external devices and networks.

4. Mass Production and Quality Control

With the increasing market demand for smart gateways, PCBA manufacturing has gradually entered the stage of large-scale production. In this process, automated production equipment, such as automatic placement machines and wave soldering machines, have been widely used. At the same time, strict quality control processes are essential, including automated testing methods such as online inspection (AOI) and functional testing (ICT) to ensure that each PCBA meets design specifications and has high reliability. And through a complete production monitoring and quality tracking system, defects in the production process can be discovered and corrected in a timely manner, thus ensuring the consistency and performance stability of the final product.

HoYoGo is an international, professional and reliable PCBA manufacturer. We have our own factory and advanced machines. With our own production capacity, we can provide you with one-stop service from small, medium to large batch production. Whether it is HDI PCB, gold finger PCB, hard gold PCB, flexible PCB, rigid-flex PCB, IMS PCB, quick turn PCB or PCBA, we can meet your needs.