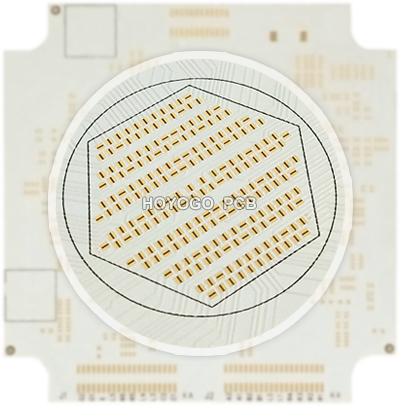

With the rapid development of LED lighting technology, people's requirements for the performance and reliability of LED lamps are also continuously increasing. As a key component of LED lamps, the PCB plays a core role in supporting and connecting the circuits. Among the many PCB materials, ceramic PCB has become an important choice in LED lighting applications due to its excellent heat dissipation, high temperature resistance, electrical insulation and other properties.

1. Heat Dissipation

LED lighting generates a lot of heat when working, especially in high-power, high density application scenarios. If the heat cannot be dissipated efficiently, the operating temperature of the LED chip will rise significantly, thereby affecting its luminous efficiency and service life. Traditional FR4 materials have poor thermal conductivity, while ceramic materials, such as aluminum oxide (Al2O3) and aluminum nitride (AlN), have extremely high thermal conductivity. In particular, aluminum nitride has a higher thermal conductivity and is suitable for high-power LED lighting equipment that requires efficient heat dissipation. It can quickly conduct heat and keep the temperature of the LED chip within a reasonable range, thereby improving its stability and lifespan.

2. High Temperature Resistance

Some LED lighting equipment often needs to operate for a long time. In this case, high temperature resistance becomes the key to ensure the stable operation of the lamp. The ceramic material itself has extremely high temperature resistance and can maintain stable physical and electrical properties in an environment above 200℃. In contrast, traditional FR4 materials are prone to thermal expansion and material degradation at high temperatures, while ceramic PCBs can avoid this problem and ensure that LED lamps can work normally in high temperature environments. Ceramic PCBs are particularly suitable for temperature-sensitive occasions such as outdoor lighting and industrial lighting.

3. Electrical Insulation

In LED lighting, electrical insulation is an important consideration. High-power LED lamps operate at a high voltage, and ceramic materials have excellent electrical insulation properties, which can effectively isolate current and prevent electric leakage or short-circuit accidents. Compare with PCBs made of metal materials, ceramic PCBs can not only provide high thermal conductivity, but also ensure the electrical insulation effect. This feature is especially critical in high-power, high-density LED lighting systems, providing higher safety and stability for LED lamps.

4. Thermal Expansion Coefficient

The thermal expansion coefficient of Ceramic PCB is close to that of LED chip materials(such as silicon), which means that the expansion and contraction of ceramic PCB and LED chip are almost synchronized when the temperature changes, and no obvious thermal stress will be generated. The reduction of thermal stress can effectively avoid solder joint cracks or circuit breaks caused by thermal cycles, greatly improving the reliability and durability of LED lamps. So, in LED lighting applications that frequent switching or work under extreme temperature conditions, the thermal expansion characteristics of ceramic PCBs show irreplaceable advantages.

5. Chemical Stability

LED lighting equipment is widely used in complex scenarios such as outdoor, industrial, and marine environments, where factors such as moisture, salt spray, and chemical corrosives may exist. Ceramic materials themselves have strong chemical corrosion resistance and are not easily affected by moisture and chemicals. Compared with other materials, ceramic PCBs perform more stably in harsh environments and are suitable for outdoor and industrial LED lighting applications that require high durability, which can effectively reduce maintenance and replacement costs.

6. Miniaturization

Some LED lighting devices pursues miniaturization and lightweight, while the high strength and stability of ceramic PCB enables it to support smaller and more compact structural designs. Compared with traditional PCB materials, ceramic PCBs can carry high-density component layouts more effectively and are suitable for space-constrained lighting applications such as automotive LED lighting, LED backlighting for mobile devices, etc.

HoYoGo is an international, professional and reliable ceramic PCB manufacturer, with many years of experience in ceramic PCB production. We can realize the production of high-tech, high-quality, high-difficulty and high-performance PCB, and can guarantee the quality and reliability of each product delivered to customers. If you have the need to make ceramic PCB, please contact us!