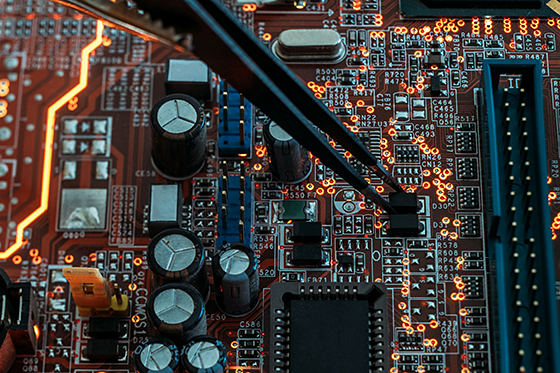

The widespread application of Internet of Things (IoT) technology has profoundly influenced printed circuit boards (PCBs). With the growing demand for IoT devices, PCBs have undergone necessary reforms and innovations in design, materials, and manufacturing technologies to meet the special needs of IoT applications.

1. High-Density and Miniaturized Designs

Since IoT devices are small in size and need to have multiple functions, they place high demands on the miniaturization and high-density wiring of PCBs. High-density interconnects (HDI) and multi-layer PCBs have become common choices in IoT devices to support efficient circuit design and increase the number of components to achieve complex functions in a limited space.

2. Higher Reliability and Durability

IoT devices need to operate in complex and changing environments, such as high temperatures, large humidity fluctuations, and environments with strong electromagnetic interference. Therefore, IoT-specific PCBs usually use materials with higher reliability, such as high-temperature-resistant polyimide or ceramic substrates, to ensure their long-term and stable operation. Additionally, these PCBs require strong anti-interference capabilities to operate effectively in challenging electromagnetic environments.

3. Low-Power Design

Many IoT devices are battery-powered, necessitating strict adherence to energy consumption limits. In the design process of IoT PCB, special attention should be paid to low power design, such as selecting energy-efficient components, optimizing circuit design, and adopting appropriate energy-saving technologies. This design not only reduces the PCB's energy consumption but also effectively extends the device's battery life, allowing the device to maintain a longer working cycle.

4. Support for Wireless Connectivity

IoT Devices usually rely on wireless communication technologies such as Wi-Fi, Bluetooth, and Zigbee. Consequently, PCBs must integrate corresponding wireless modules and implement signal optimization designs to ensure stable transmission and adequate coverage. This requires the PCB to have a reasonable layout and isolation design to reduce signal interference problems in wireless communications.

5. Adaptability to Mass Production and Customization

The production demand for IoT devices is huge, and the stability, reliability and speed of PCB manufacturing are high. Therefore, it is necessary to take into account the needs of both mass production and rapid customization. In this regard, the importance of automation and intelligent manufacturing is self-evident. They can achieve efficient production processes, shorten product launch cycles, and improve product quality and competitiveness.

6. Data Transmission and Processing Capabilities

IoT PCBs must have the capability to process and transmit data quickly to meet the real-time response requirements of devices. This includes embedding more microprocessors and memory components in PCBs to enable the collection, storage and processing of large amounts of data. In addition, advanced integrated circuit (IC) packaging technology has also been applied to adapt to miniaturized designs while improving computing power.

7. Security Considerations

With the widespread application of IoT devices, data security becomes increasingly important. During the PCB design process, we need to take more stringent security measures at the hardware level, such as integrating encryption modules into circuit boards and strengthening data protection mechanisms to prevent data from being tampered with or equipment from being maliciously attacked.

The development of IoT technology has driven continuous innovation in the PCB industry to better meet numerous demands, such as miniaturization, high reliability, low power consumption, and enhanced security. As IoT applications deepen, PCBs will continue to evolve in materials, manufacturing technologies, and integration technologies, providing essential support for the proliferation and efficient operation of IoT devices.

HOYOGO is an international, professional and reliable PCB manufacturer. The management team has an average of 25 years of industry experience. We also have 2 factory production bases with a monthly production capacity of 500,000sqm. With our rich experience, production capacity and resources, we can provide you with one-stop service from small to large batch production.