As the core component of electronic devices, medical PCBs play a vital role in the field of smart medical equipment. In these devices, medical PCBs not only carry various complex circuits and components, but also support the efficient operation, data transmission, and precise diagnostics. Given the medical industry’s high requirements for the reliability, precision, and safety of equipment, the application of PCBs in smart medical devices is particularly critical.

1. High Integration and Miniaturization

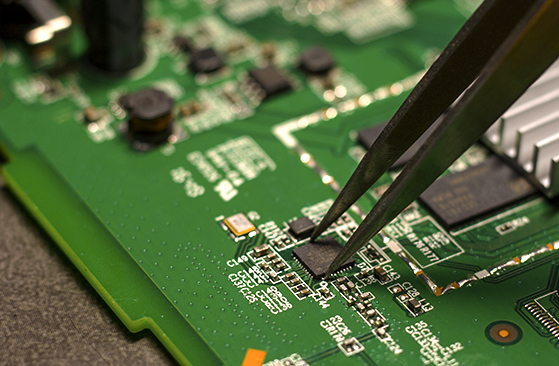

Smart medical devices are usually compact and multifunctional, especially portable and implantable devices, which are easier to carry and implant. Medical PCB can integrate various electronic components into one, saving space and realizing complex electrical and data processing functions. For example, flexible medical PCBs (FPCs) have excellent bending properties and are suitable for devices that require compact layouts and flexible shapes, such as wearable monitors, endoscopes, and micro sensors.

2. High Reliability and Durability

Medical equipment is often used in challenging environments, requiring stable operation under extreme temperature, humidity, and electromagnetic interference. So, medical PCBs must have high reliability to ensure that no electrical failures occur during long-term operation. For these high-demand medical devices, multi-layer PCBs and heavy copper PCBs are usually widely adopted to ensure the current stability and reliability of electrical performance. Medical PCBs that undergo rigorous quality control can support critical vital signs monitoring and emergency medical treatment.

3. Supporting Data Transmission and Wireless Communication

The key technology of telemedicine equipment is reflected in real-time data transmission and monitoring. The medical PCB embedded in the device integrates wireless communication modules, enabling data exchange between the device, the cloud, and other devices. With the support of medical PCBs, the communication functions can transmit patient data to the medical platforms for analysis in real time, which plays a vital role in remote diagnosis, patient tracking and intelligent medical applications.

4. Supporting AI and IoT Modules

The operation of smart medical equipment relies on AI algorithms to process large amounts of physiological data. The efficient and stable operation of AI chips requires the support of high-quality medical PCBs. High-density interconnect (HDI) medical PCBs have more wiring layers and more compact connections, which can ensure fast calculation and real-time feedback of AI chips. At the same time, the sensors and processing units on medical PCBs support Internet of Things (IoT) technology, which can realize the interconnection of medical equipment.

5. Power Management and Power Consumption Optimization

In the field of smart medical devices, especially portable and implantable devices, efficient power management and power consumption optimization are particularly important. By integrating efficient power management modules, medical PCBs can provide stable power to devices while reducing energy consumption and extending the battery life of devices. Low power consumption is critical for medical devices, ensuring long-term operation without frequent battery replacement or charging, improving the patient experience.

6. Electromagnetic Compatibility and Safety

PCBs in smart medical devices must meet strict electromagnetic compatibility (EMC) requirements to ensure that the devices do not interfere with the normal operation of other medical devices during operation. Medical PCB designs use shielding technology and optimized routing solutions to prevent electromagnetic interference and noise. At the same time, medical PCBs must also comply with the safety standards of medical devices, preventing risks from electrical failures to ensure patient safety.

HoYoGo is an international, professional and reliable medical PCB manufacturer, certified with ISO13485. We consistently adhere to the highest industry standards in our production, engineering and procurement teams. We have long-term experience and professional technological knowledge in medical PCBA assembly. If you have relevant needs, you are welcome to send us an inquiry.