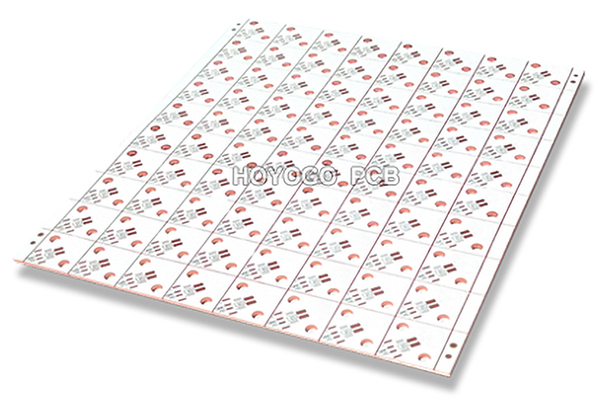

First. One of the main advantages of deposited copper is its lower ground impedance. A large part of the so-called anti-interference is caused by the reduction in ground impedance. It is generally believed that for circuits composed entirely of digital equipment, a large areas of ground should be laid. For analog circuits, in addition to high-frequency circuits, the ground loop formed by deposited copper can also cause electromagnetic coupling interference. So, not all circuits need to deposit copper. In addition, the performance of mesh copper deposition is superior to filled copper deposition.

The significance of placing polygon planes on a circuit is:

1. Connect deposited copper and ground wire to reduce loop area.

2. Copper deposited over a large area is equivalent to reducing the resistance of the ground wire and reducing the voltage drop.

From these two points, whether it is digital ground or analog ground, copper should be deposited to improve the anti-interference ability. At high frequencies, the two grounds should also be separated to deposit copper, and then connected to a single point, you can use a wire to wrap it around the magnetic ring several times, and then connect.

However, if the frequency is not too high, or the working conditions of the instrument are not bad, the distance between the power line and the ground line can be relatively wide.

The crystal can be counted as a high-frequency emission source in the circuit. You can deposit copper around it and then ground the crystal shell to make it better.

Third. What is the difference between placed polygon plane block and grids?

Specifically, there are about 3 functions:

1. Beautiful.

2. Noise suppression.

3. In order to reduce high frequency interference.

According to the wiring guidelines: Why should the power line and ground line be as wide as possible, and increase the grid? Is this not against the principle? If you look at it from a high-frequency perspective, it is even more wrong. The most taboo in high-frequency wiring is sharp traces. There are many 90-degree wiring on the power layer, so there are many problems.

In fact, this is entirely a technical requirement. We need to see if the hand-welded lines are drawn with traces similar to this angle, but you will find few such traces.

If you see traces drawn in this way, you must mount a surface-mount chip on it because there is a process called wave soldering when you place the chip. If the circuit board is to be locally heated and the copper has been completely deposited, the specific thermal coefficients on both sides will be different, the circuit board will warp, and once the circuit board warps, problems will occur.

If you put on the steel cover, it is very easy to make mistakes on the pins of the chip, so the scrap rate will go straight up. In fact, this approach also has disadvantages.

Of course, there are also surface mounts that do not have a grid added. From the perspective of product consistency, there may be three cases:

1. Corrosion technology is very good.

2. Instead of wave soldering, a more advanced reflow welding is used, but in this case, the investment of the entire assembly line is up to 3 to 5 times.

Signal integrity requirements. Provide a complete return path for high-frequency digital signals and reduce the wiring of DC networks. Of course, there are reasons for heat dissipation, special equipment installation requirements, etc.