In the field of lighting, high-power LEDs have become the preferred choice for many lighting projects due to their exceptional brightness and wide range of applications. As the core component of high-power LEDs, the high-power LED PCB plays a crucial role. It offers a series of significant advantages, providing a solid foundation for the efficient and stable operation of high-power LEDs.

1. Excellent Heat Dissipation

High-power LEDs generate substantial heat during operation. If not dissipated effectively, this heat can severely impact the lifespan and performance of the fixture. High-power LED PCBs are designed with specialized materials and structures to greatly improve thermal management.

The substrate typically employs metal base materials (such as aluminum or copper), which have excellent thermal conductivity, allowing rapid heat transfer away from the fixtures. For example, aluminum base PCBs have significantly higher thermal conductivity than standard FR-4 materials, allowing heat from the chip to be quickly and efficiently transferred to the heat sink.

Additionally, the copper foil on the PCB surface is optimized to increase the heat dissipation area, further improving efficiency. Effective heat dissipation performance ensures that the chip and other components operate within a reasonable temperature range during extended use, avoiding problems such as light decay and shortened lifespan due to overheating, and effectively improving the stability and reliability of the fixture.

2. Superior Electrical Performance

High-power LEDs demand strict electrical performance, and high-power LED PCBs excel in this aspect. They provide stable electrical connections, ensuring accurate and efficient current distribution to each light-emitting unit.

The circuit layout on the PCB is carefully designed, using reasonable line width, spacing and wiring rules, which effectively reduces the line resistance and inductance, and reduces the loss and interference during signal transmission. At the same time, the high-power LED PCB has good insulation performance, which can prevent the occurrence of electrical short circuits and leakage, ensuring the safe operation of the fixture.

In addition, through optimized design, high-power LED PCB can also achieve precise control of multiple light-emitting units to meet different lighting needs, such as dimming, color adjustment and other functions, which improves the intelligence level and user experience of high-power LEDs.

3. High Mechanical Strength and Stability

High-power LED often endure mechanical stresses such as vibration and impact during installation and use. High-power LED PCBs exhibit high mechanical strength and stability, making them suitable for various demanding environments. The substrate materials and structural design provide strong resistance to bending and impact, reducing the risk of deformation or damage.

During the production process, strict process control and quality inspection are used to ensure the dimensional accuracy and surface flatness of the PCB, thereby ensuring the installation accuracy and reliability of components. This high mechanical strength and stability not only extend the service life of the PCB, but also ensure the overall structural stability of the high-power LED, reducing the likelihood of mechanical failures during long-term use.

4. High Degree of Customization

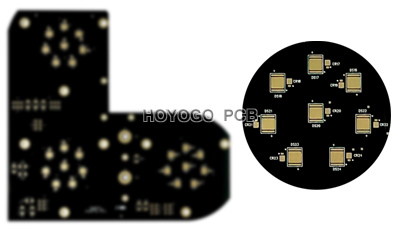

Different high-power LED applications scenarios have different requirements for PCBs, and high-power LED PCBs have strong customizable options. From size and shape to circuit layout and component packaging, everything can be customized according to specific design requirements. For example, in some special lighting devices, the PCB may need to have a special shape to fit into a small space; in smart lighting systems, more sensors and control chips may need to be integrated on the PCB.

Through customized design, high-power LED PCB can perfectly meet various complex design requirements, providing broad space for innovative applications of high-power LEDs. Moreover, customization helps improve production efficiency, reduce costs, and meet the market’s diverse demands for high-power LEDs.

5. Production Efficiency and Cost Advantages

In mass production, standardized designs and manufacturing processes for high-power LED PCBs help improve production efficiency. The use of advanced automated equipment and technologies, such as surface mount technology (SMT), can achieve fast and precise component installation, greatly shortening the production cycles.

Meanwhile, due to the high reliability and stability of high-power LED PCBs, the failure rate and maintenance cost of the product are reduced, which in the long run reduces the overall cost of the entire high-power LED product. In addition, as technology continues to advance and production scales expand, the manufacturing cost of high-power LED PCBs is gradually decreasing, making them more competitive in the market.

6. Strong Environmental Adaptability

High-power LEDs are often used in different environmental conditions, such as outdoor, humid, high temperature and other harsh environments. High-power LED PCB has strong environmental adaptability through special protection treatment and material selection. For example, the use of conformal coating spraying technology can effectively prevent the PCB from being corroded by moisture, salt spray, and mildew, etc; in high-temperature environments, the use of high-temperature resistant materials and packaging technology can ensure that the PCB can work normally. This strong environmental adaptability enables high-power LEDs to operate stably in a variety of complex environments, broadening the application range of high-power LEDs. Whether in urban lighting, industrial lighting or special environment lighting, they can perform excellently.

HoYoGo is an in international, professional and reliable high-power LED PCB manufacturer. We have our own factory, advanced machines, and excellent and stable quality system. We provide one-stop PCB solutions, supporting complex technologies and offering competitive pricing on metal materials. If you have related needs, please feel free to contact us!