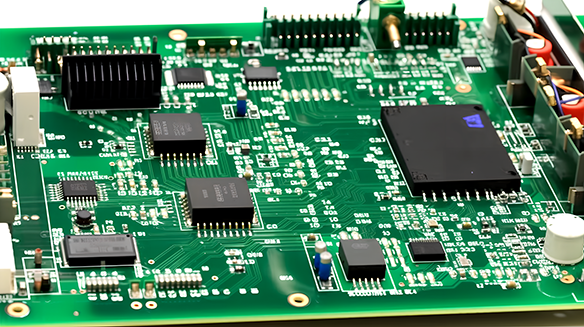

Industrial control PCBs are specially designed for applications in the industrial control field. They play a critical role in providing electrical connections for electronic components and are one of the core components in industrial control systems. So, what are the advantages of industrial control PCBs?

1. High Reliability

Industrial environments are complex and variable, often involving harsh conditions such as high temperatures, high humidity, dust, vibration, and strong electromagnetic interference. Industrial control PCBs are designed and manufactured using high-quality materials and advanced processes to ensure long-term stable operation under these adverse conditions, minimizing the risk of failures and ensuring uninterrupted industrial production.

2. High Stability

Unlike consumer electronics, industrial equipment is often required to operate continuously over extended periods. Industrial control PCBs employ optimized circuit designs and rigorously screened electronic components to maintain stable performance and precise signal output during prolonged operation, meeting the stringent stability demands of industrial control systems.

3. Strong Anti-Interference Capability

Industrial sites contain many sources of electromagnetic interference, such as motors and inverters, which generate intense electromagnetic radiation during operation. Industrial control PCBs utilize specialized wiring designs, multilayer PCB structures, and shielding measures to effectively resist external electromagnetic interference while minimizing their own electromagnetic emissions. This ensures accurate and complete signal transmission between electronic components in the system.

4. High and Low Temperature Resistance

Industrial equipment is deployed in diverse scenarios, ranging from high-temperature environments near furnaces to cold outdoor settings. Therefore, industrial control PCBs are made from materials capable of withstanding a broad temperature range, typically operating reliably between -40°C to +85°C or even more extreme conditions. This ensures reliable operation of the equipment in different environmental temperatures.

5. High Degree of Customization

Different industrial control applications have vastly different functional requirements, ranging from simple device control to complex automated production line systems. To meet these diverse needs, industrial control PCBs are highly customizable. They can be tailored to specific functional requirements, size constraints, interface types, and other application-specific demands during design and manufacturing.

HoYoGo is an international, professional and reliable industrial control PCB manufacturer. We strictly adhere to the ISO 9001 quality management system, with every step from raw material procurement to final product delivery undergoing rigorous inspection and control. Using high-quality high-Tg substrates, environmentally friendly solder mask inks, and advanced production equipment and technologies, our industrial control PCBs offer excellent electrical performance, high-temperature resistance, and corrosion resistance. Whether in harsh industrial environments or under prolonged continuous operation, our products consistently maintain stable performance, ensuring the reliable operation of your equipment.