With the rapid growth of the new energy vehicle market, the demand for battery management systems, motor control and power conversion equipment is also increasing. These systems ...

2024/08/02

PCB plays a vital role in intelligent robots. Its main function is not only to provide physical support and electrical connections for the robot, but also to integrate the comple...

2024/07/31

As the demand for automotive electronic equipment continues to grow, how to improve the reliability and performance of electronic components has become a critical problem. In thi...

2024/07/26

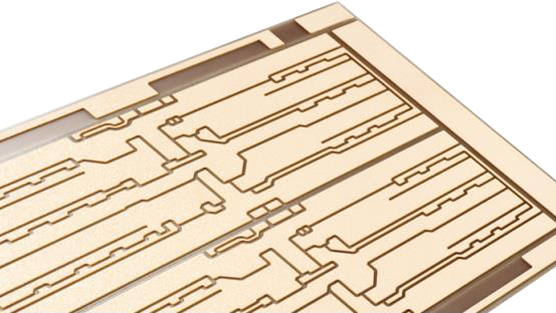

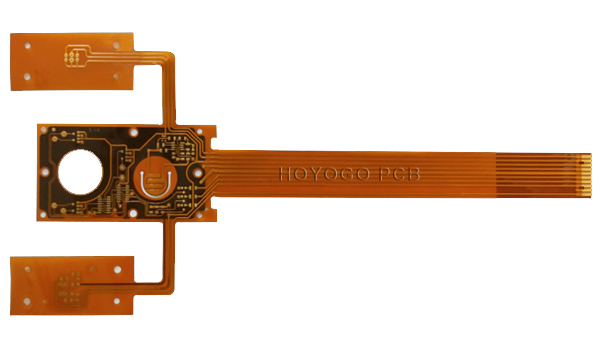

With the rapid development of electronic technology, FPC is used more and more widely in electronic products. The substrate of FPC is its key component, and the type of copper fo...

2024/07/24

Automotive infotainment systems have gradually become a core component of vehicles, not only providing drivers with necessary information, but also greatly improving the driving ...

2024/07/19

With the continuous development of automobile technology, driving experience and ride comfort have been significantly improved. In this process, PCBs play a crucial role. Automot...

2024/07/17

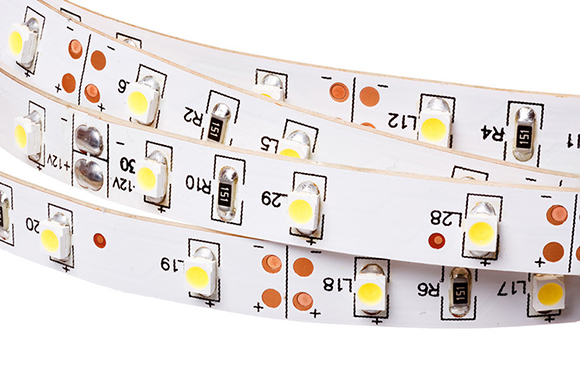

With the continuous advancement of technology, LED(light emitting diode) technology has become an indispensable part of our daily life. As the core component of LED products, LED...

2024/07/12

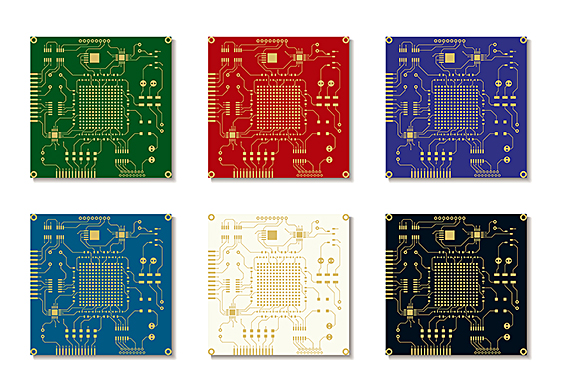

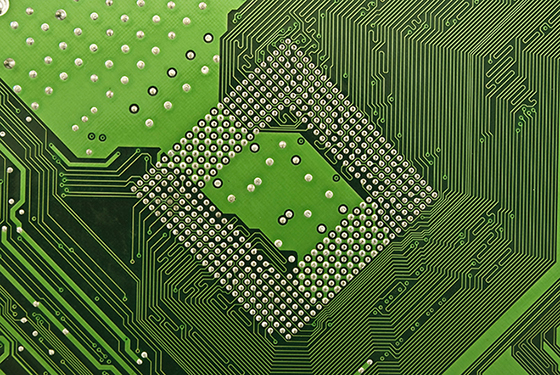

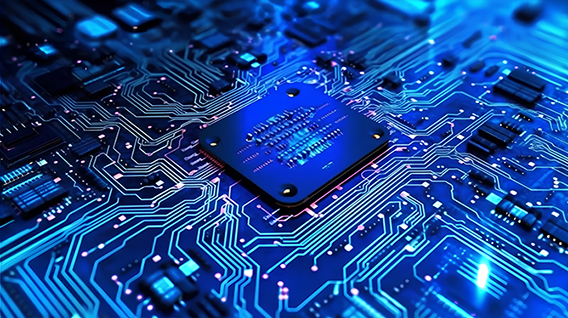

With the rapid development of artificial intelligence technology, the demand for PCB in AI servers is also increasing. Among many types of PCB, HDI PCB has become the preferred s...

2024/07/10

Medical display PCB is a circuit board specially designed for medical display equipment. Its main function is to process and present medical images, including various types, such...

2024/07/05

Automotive radar PCBs are one of the key components in automotive electronic systems. They are used to support a variety of radar systems, which play a vital role in th...

2024/07/03